Introduction

In industrial piping, the “weakest link” is rarely the pipe itself—it is the connection.

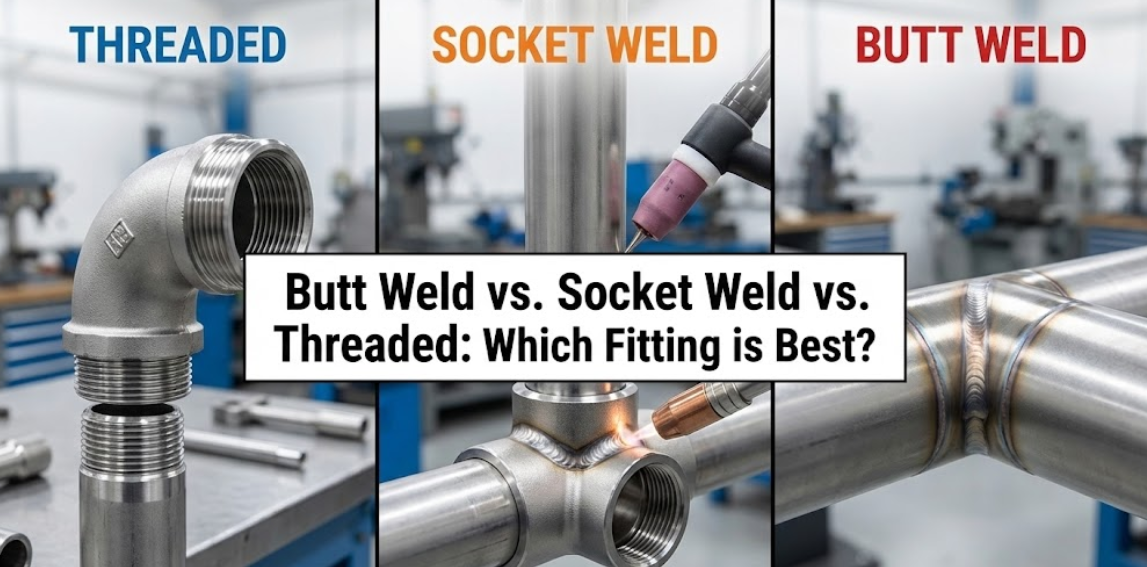

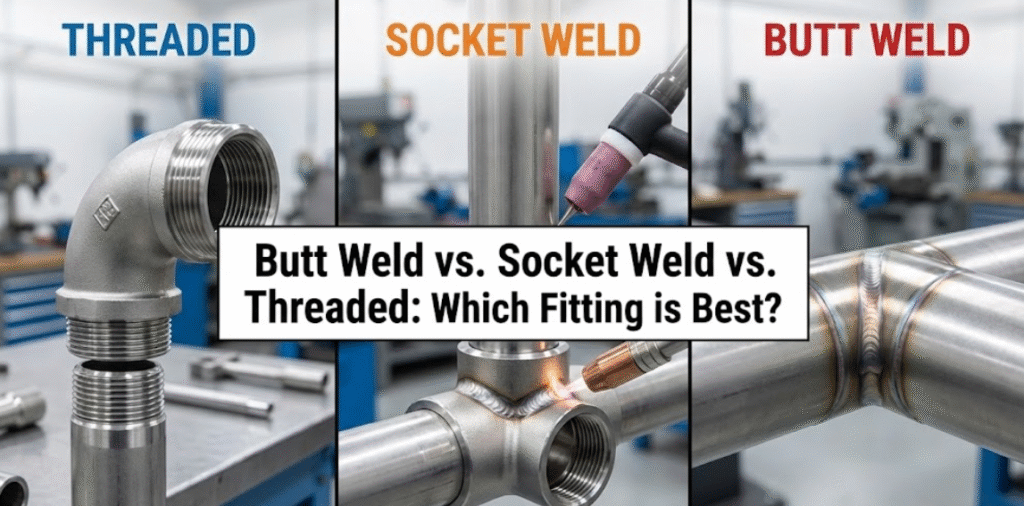

When designing small-bore piping systems (typically 2 inches and below), engineers must choose between three common connection types: Threaded (Screwed), Socket Weld, and Butt Weld.

Making the wrong choice here doesn’t just mean a bad fit; it means dangerous leaks, vibration failures, and “crevice corrosion” that can shut down your plant.

At Dhanvika Global, we stock all three types, but we want you to buy the one that will actually last. Here is our technical breakdown.

1. Threaded Fittings (The “Easy” Choice)

Threaded fittings connect by screwing the pipe into the fitting. No welding is required.

- Pros: Quick installation; no need for a qualified welder; easy to disassemble for maintenance.

- Cons: High risk of leakage. Under vibration or thermal cycling (hot/cold shifts), threads loosen over time.

- Best For: Low-pressure water lines, fire protection, and non-critical instrument air.

- Warning: Never use threaded fittings for toxic gas or flammable fluids.

2. Socket Weld Fittings (The “Middle Ground”)

In a Socket Weld, the pipe is inserted into a recessed area (the socket) of the fitting, and then a fillet weld is applied on the outside.

- Pros: Much stronger than threaded; easier to align than butt weld (the socket holds the pipe in place).

- Cons: The gap inside the fitting can trap fluid, leading to “Crevice Corrosion.”

- Best For: Steam, oil, and gas lines under 2 inches where leakage is not an option.

3. Butt Weld Fittings (The “Heavy Duty” King)

Butt Weld fittings are beveled at the ends and welded directly to the pipe, creating a seamless, solid joint.

- Pros: The strongest connection possible. Full penetration weld means no crevices and smooth flow (low pressure drop).

- Cons: difficult to install. Requires expert beveling and precise alignment.

- Best For: Critical high-pressure lines, corrosive chemicals, and nuclear applications.

⚔️ Technical Comparison Table

| Feature | Threaded (Screwed) | Socket Weld (SW) | Butt Weld (BW) |

| Connection Style | Screwed (NPT/BSP) | Fillet Weld | Full Penetration Weld |

| Leakage Risk | High (especially with vibration) | Very Low | Zero (Strongest) |

| Installation Speed | Fast (No Welding) | Medium | Slow (Requires prep) |

| Corrosion Risk | Low | High (Crevice Corrosion) | Low |

| Typical Size Range | 1/8″ to 4″ | 1/8″ to 2″ (Small Bore) | 1/2″ to 72″+ |

💰 The “Hidden Cost” of Installation

When comparing prices, don’t just look at the fitting cost. Look at the labor cost.

- Threaded: Cheapest Material + Cheapest Labor = Lowest Initial Cost.

- Butt Weld: Moderate Material + Expensive Labor (Expert Welder + X-Ray testing) = Highest Initial Cost.

However, if a Threaded fitting leaks toxic chemicals, the “clean-up cost” is 100x higher than the welding cost. Cheap is expensive in the long run.

🏭 Dhanvika Case Study: Solving Vibration Leaks

A hydraulic press manufacturer in Chennai approached us with a recurring problem. They were using Threaded Forged Fittings (3000#) on their hydraulic lines. Because the machines vibrated heavily during operation, the threads constantly loosened, causing oil sprays on the factory floor.

Our Recommendation:

We advised them to switch to Socket Weld Fittings (Class 3000). The fillet weld creates a permanent bond that is immune to vibration.

The Result:

After retrofitting the lines with Socket Weld fittings supplied by Dhanvika Global, the leakage stopped completely, improving workplace safety and reducing oil waste.

Conclusion

- Use Threaded for non-critical, low-pressure utilities (Water, Air).

- Use Socket Weld for high-pressure small pipes (Steam, Oil) where welding is allowed.

- Use Butt Weld for critical, corrosive, or large-diameter lines where flow efficiency is key.

Still unsure if your drawing requires Socket Weld or Threaded? Send us your Bill of Materials (BOM) and our technical team will verify it for you.