Introduction

From the outside, a Gate valve and a Globe valve often look remarkably similar. They both have a handwheel at the top and a body that connects within the pipeline.

Because they look similar, procurement managers often swap them based on price or availability. This is a critical mistake.

Inside the valve body, they function in completely opposite ways. Using the wrong one can lead to severe pressure drops, damaged valve seats, and system failure.

At Dhanvika Global, we supply industrial valves for critical steam, oil, and gas applications. Here is the simple rule we tell every engineer: One is a stop sign; the other is a dimmer switch.

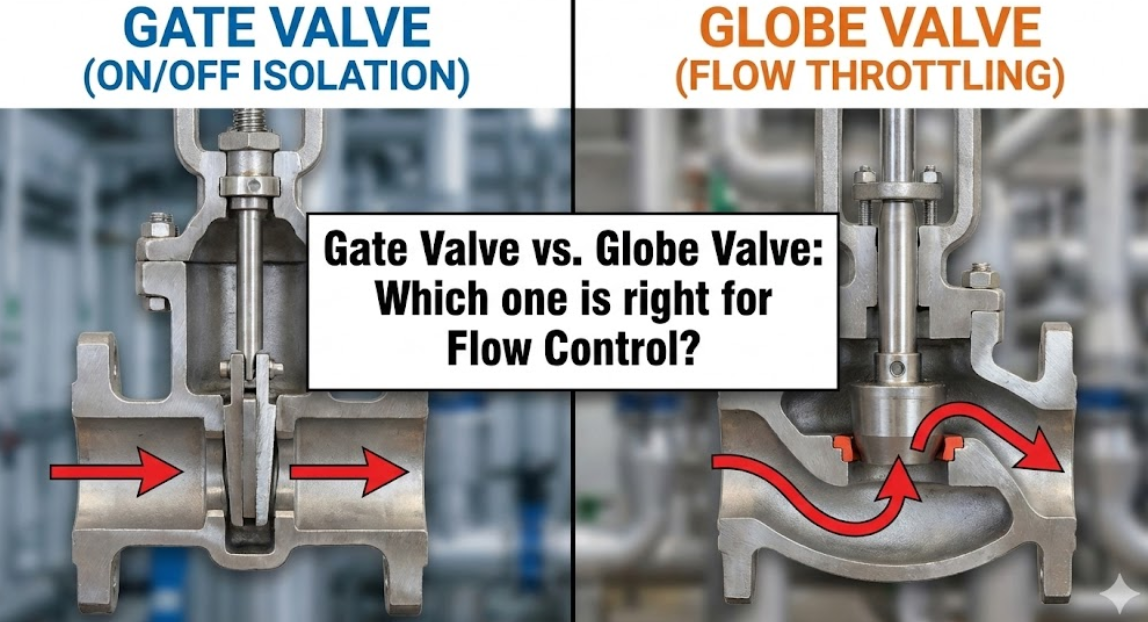

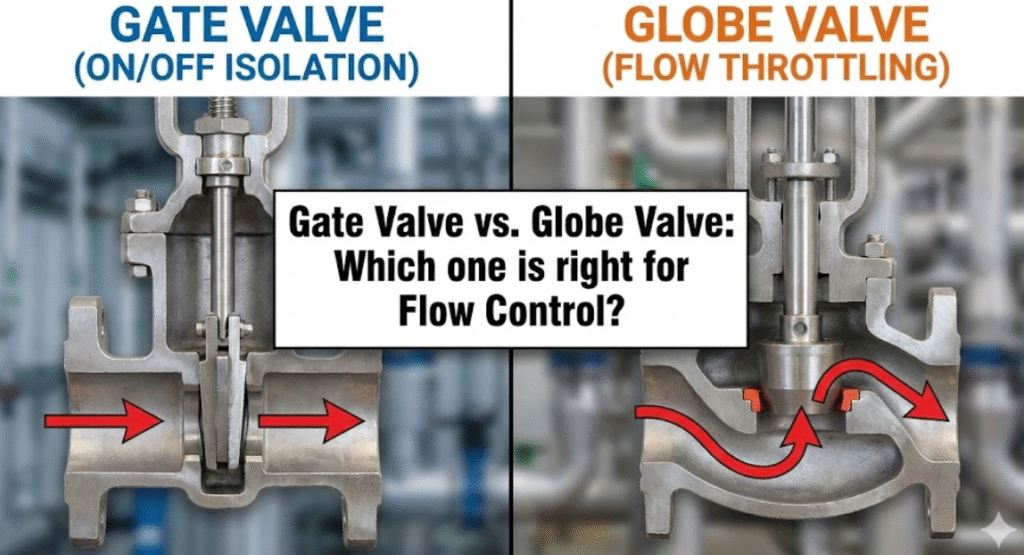

1. The Gate Valve (The “Stop Sign”)

A Gate valve is designed for one purpose only: On/Off isolation. It works by lowering a flat “gate” or wedge into the path of the fluid, completely blocking it.

- How it works: When fully open, the gate lifts entirely out of the flow path, offering almost zero resistance to the fluid.

- The Golden Rule: A Gate valve must be either 100% Fully Open or 100% Fully Closed.

- What happens if you throttle it? If you leave it half-open to regulate flow, the high-velocity fluid will vibrate the gate against the seat, causing rapid erosion (called “wire drawing”). The valve will soon fail to seal properly.

- Best For: Isolating a section of pipe for maintenance.

2. The Globe Valve (The “Dimmer Switch”)

A Globe valve is designed for throttling and regulating flow. Inside, the fluid is forced to change direction twice in an “S-shape” path, flowing up through a seat ring against a plug.

- How it works: Because the fluid has to turn corners, it naturally slows down. You can screw the plug down partially to finely tune the amount of flow passing through.

- The Trade-off: Because of the internal “S-shape,” a Globe valve creates a significant high-pressure drop even when fully open. Your pumps have to work harder to push fluid through it compared to a Gate valve.

- Best For: Controlling cooling water flow, regulating steam pressure, or bypass lines.

⚔️ Technical Showdown

| Feature | Gate Valve | Globe Valve |

| Primary Function | Isolation (On/Off) | Throttling (Regulation) |

| Can be used half-open? | NO (Will damage seat) | YES (Designed for it) |

| Pressure Drop | Very Low (Smooth flow) | High (Turbulent flow) |

| Flow Direction | Bi-directional (Either way) | Uni-directional (Must follow arrow) |

| Operation Speed | Slow (Many turns to open) | Faster (Fewer turns) |

💰 The “Hidden Cost” of the Wrong Choice

Gate valves are generally cheaper to buy than Globe valves. This tempts buyers to use Gate valves everywhere.

However, the hidden cost is operational.

If you use a cheap Gate valve to throttle high-pressure steam, you might save money on the purchase, but you will likely have to replace that valve within six months due to seat damage. A proper Globe valve, while more expensive initially, would last for years in that same throttling application.

🏭 Dhanvika Case Study: The Leaking Steam Line

A textile plant in Ahmedabad called us regarding persistent leaks in their boiler steam lines. They were using Cast Steel Gate Valves to manually regulate the steam pressure going to their dyeing machines.

The Problem:

The operators were leaving the Gate valves 30% open to control the pressure. The high-velocity steam rapidly eroded the bottom of the gate wedge. When they eventually tried to close the valve completely for maintenance, it wouldn’t seal, and steam continued to leak.

Our Solution:

We replaced the damaged Gate valves with correct Globe Valves with Stellite-hardened seats.

The Result:

The operators could now accurately control pressure without damaging the valve, and the plant stopped losing expensive steam during shutdowns.

Conclusion

The rule is simple:

- If you need to stop the flow completely, buy a Gate Valve.

- If you need to control how much flow passes, buy a Globe Valve.

Need help selecting the right valve material (Cast Iron, Cast Steel, or Stainless Steel) for your medium? Send us your inquiry and our technical team will quote the right option.