Introduction

When ordering pipe, getting the right material (like Stainless Steel) is only half the battle. The second half is getting the right thickness, known as the Pipe Schedule.

The most common question our sales team gets is: “What is the difference between Schedule 40 and Schedule 80, and why does Sch 80 cost so much more?”

Choosing the wrong schedule is dangerous. Too thin, and the pipe could burst under pressure. Too thick, and you are wasting tens of thousands of rupees on unnecessary steel and reducing your flow rate.

At Dhanvika Global, we help you calculate the exact thickness required for your application. Here is the simple breakdown.

The Golden Rule of Pipe Schedules

Before we compare them, you must understand one crucial concept:

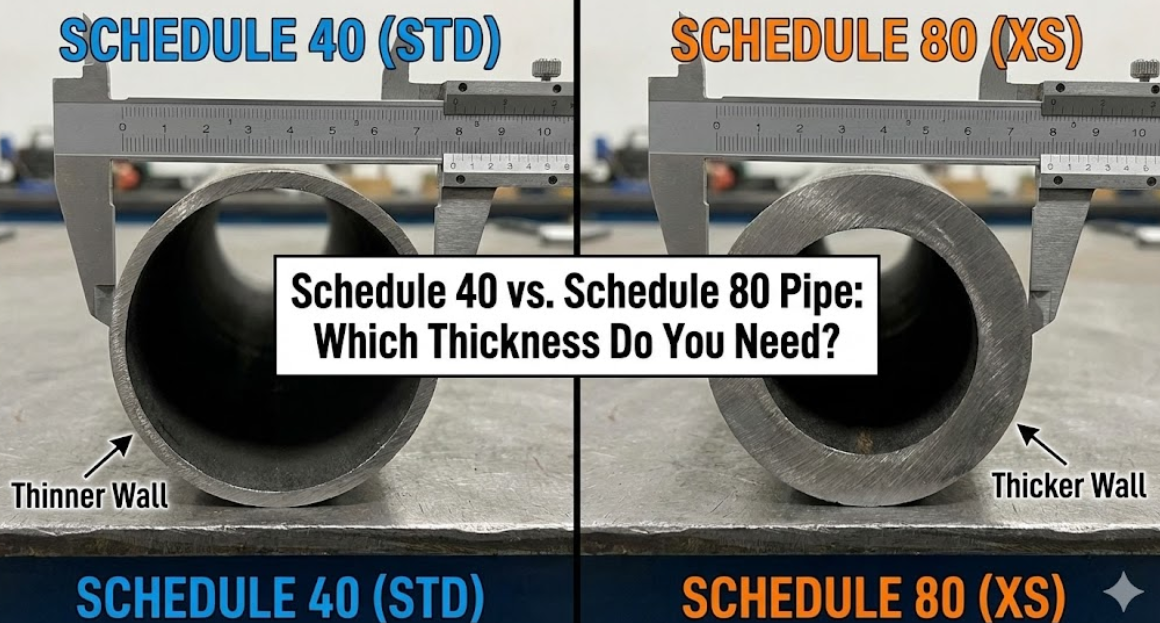

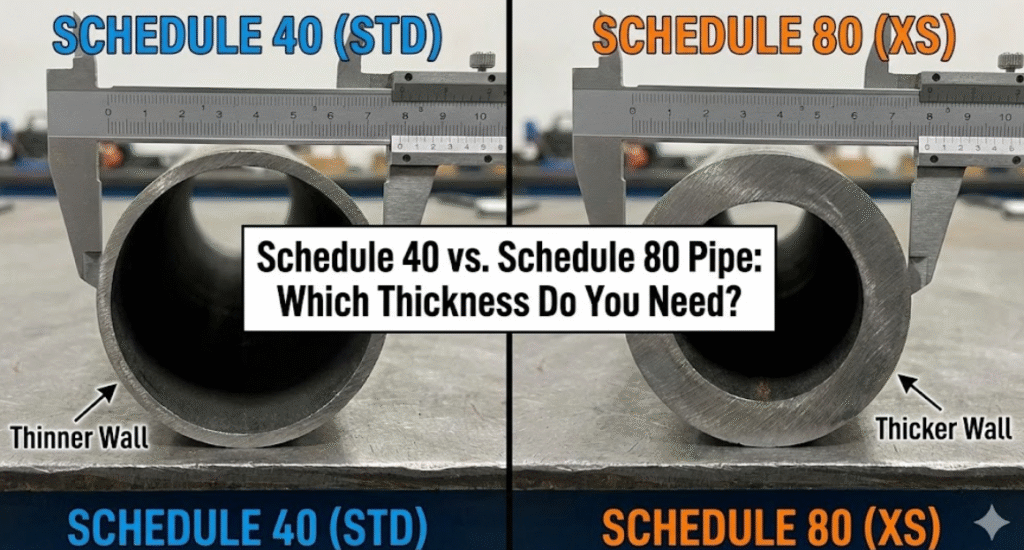

Outside Diameter (OD) remains constant. Inside Diameter (ID) changes.

Whether you buy a 2-inch Schedule 40 pipe or a 2-inch Schedule 80 pipe, the outside measurement is exactly the same (60.3mm).

- Schedule 40 has a thinner wall, so the inside hole is bigger.

- Schedule 80 has a thicker wall, so the inside hole is smaller.

1. Schedule 40 (STD – Standard Wall)

Schedule 40 is the “workhorse” of the piping industry. It is the most common thickness used in standard applications.

- Characteristics: Moderate wall thickness.

- Pressure Rating: Suitable for standard pressures (e.g., water lines up to 150-300 psi, depending on size).

- Best For: General plumbing, low-pressure chilled water, compressed air lines, and structural applications (handrails).

2. Schedule 80 (XS – Extra Strong)

Schedule 80 has a significantly thicker wall than Schedule 40.

- Characteristics: Heavy wall thickness. It is heavier and more expensive.

- Pressure Rating: Designed for high-pressure applications. It can handle roughly 40-50% more pressure than SCH 40 of the same size.

- Best For: High-pressure hydraulic lines, high-temperature steam, and chemical lines where corrosion allowance is required.

⚔️ Technical Showdown (Example: 2-inch Pipe)

| Feature | Schedule 40 (STD) | Schedule 80 (XS) |

| Outside Diameter (OD) | 60.3 mm | 60.3 mm (Same) |

| Wall Thickness | 3.91 mm | 5.54 mm (Thicker) |

| Inside Diameter (ID) | 52.5 mm | 49.3 mm (Smaller hole) |

| Pressure Rating (Approx) | Lower | Higher |

| Weight Per Meter | Lighter | Heavier (Higher freight cost) |

💰 The Trade-Off: Pressure vs. Flow

When you choose Schedule 80 for higher pressure, you make a trade-off.

Because the wall is thicker, the inside diameter is smaller. This means Schedule 80 pipes have a lower flow capacity than Schedule 40 pipes.

If you are designing a system that needs a massive volume of water moved quickly (like a fire deluge system), using Schedule 80 unnecessarily might restrict the flow too much, requiring you to buy larger, more expensive pumps.

Engineering is about balancing safety (pressure holding) with efficiency (flow rate).

🏭 Dhanvika Case Study: The Corrosive Chemical Line

A chemical processing plant in Visakhapatnam sent us an inquiry for SS 316 Welded Pipes, Schedule 40, for a line carrying a mildly corrosive acid. They chose SCH 40 to keep costs down.

Our Intervention:

We asked about the expected corrosion rate of the acid. While the pressure was low enough for SCH 40 today, the acid would eat away roughly 0.5mm of the wall per year.

We explained that a Schedule 40 pipe would become unsafe within 3-4 years. We recommended switching to Schedule 80. Even though the initial pressure didn’t require it, the extra wall thickness provided a “corrosion allowance,” ensuring the pipe would last for 10+ years.

The Result:

The client accepted the higher upfront cost of SCH 80 to avoid shutting down the plant for repiping in three years.

Conclusion

- Use Schedule 40 for standard water, air, and low-pressure gas lines where cost savings are important.

- Use Schedule 80 if you have high pressure, high temperatures, or need extra thickness to account for corrosion over time.

Do not guess pressure ratings. Send us your operating conditions (Pressure & Temperature), and we will tell you exactly which schedule is safe.

Need Carbon Steel or Stainless Steel Pipes?

We stock seamless and ERW pipes in SCH 10, SCH 40, SCH 80, and SCH 160. Request a quote today.