Introduction

In every piping BOM (Bill of Materials), flanges are a major cost component. When procurement managers see the price difference, they almost always ask: “Can we just use Slip-On flanges instead of Weld Neck?”

The answer is: It depends on the pressure.

While Slip-On flanges are cheaper to buy, they are not always cheaper to install. And if you use them in the wrong application, they can be a catastrophic safety risk.

At Dhanvika Global, we supply thousands of flanges to projects across Africa and India. Here is the honest technical advice we give our clients.

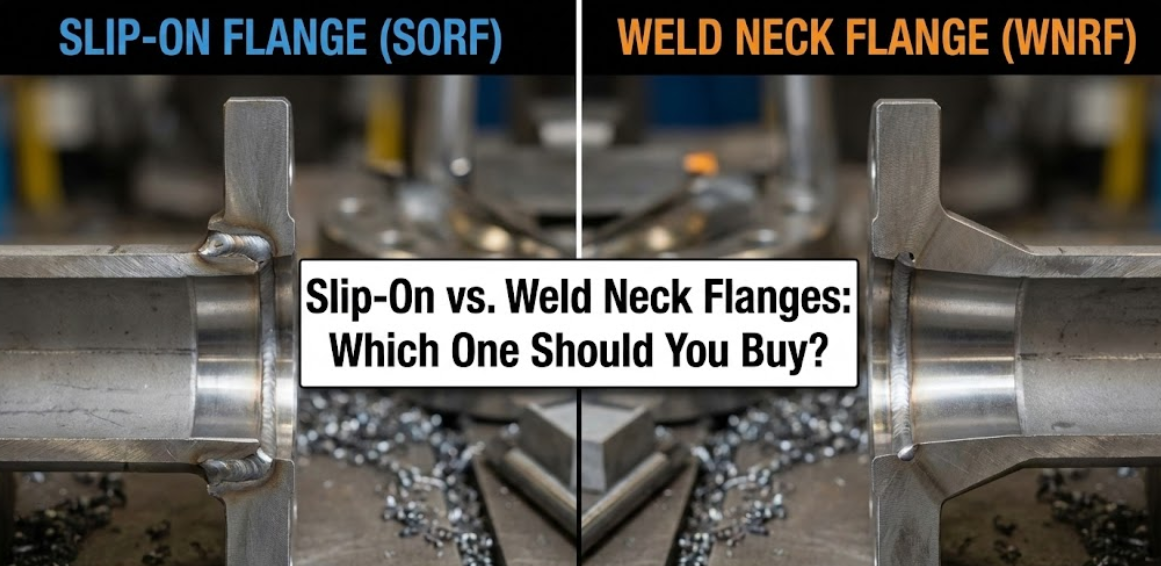

1. What is a Slip-On Flange (SORF)?

A Slip-On flange is exactly what it sounds like: a ring that “slips over” the end of the pipe. It is then welded in two places (inside and outside) to secure it.

- The Pro: The material cost is lower. It is also easier to align because the pipe slides inside, so you don’t need to cut the pipe to the exact millimeter.

- The Con: It has a lower fatigue strength (about 30% less than Weld Neck).

- Best For: Low-pressure systems, water lines, and non-critical utilities (Class 150 & 300).

2. What is a Weld Neck Flange (WNRF)?

A Weld Neck flange has a long tapered hub that matches the pipe’s wall thickness. It is connected using a single Butt Weld (V-groove).

- The Pro: The strongest flange connection available. The tapered hub transfers stress from the flange to the pipe, making it immune to high pressure and vibration.

- The Con: Expensive to buy and requires a skilled welder to perform a perfect butt weld.

- Best For: High-pressure oil & gas lines, steam lines, and sub-zero temperature applications.

⚔️ Technical Showdown

| Feature | Slip-On (SORF) | Weld Neck (WNRF) |

| Welding Required | Two Fillet Welds (Inside & Out) | One Butt Weld |

| Strength | Moderate (Risk of fatigue) | Maximum |

| Testing | Difficult to X-Ray | Easy to X-Ray (Critical for safety) |

| Flow | Turbulent (Pipe ends inside flange) | Smooth (Matches pipe ID) |

| Installation | Easy alignment | Difficult (Requires precision) |

💰 The “Hidden Cost” of Welding

Here is where most buyers get confused.

“Slip-On flanges are cheaper to buy, but Weld Neck flanges are cheaper to weld.”

- Weld Neck: Requires 1 Weld (Butt weld).

- Slip-On: Requires 2 Welds (One fillet on the outside, one on the inside).

So, while you save money on the material of a Slip-On flange, you are paying your welder double the time to weld it twice! For small projects, this balances out. But for critical timelines, double welding can slow you down.

🏭 Dhanvika Case Study: The “X-Ray” Problem

We recently supplied flanges for a Refinery Expansion Project in Gujarat. The contractor originally ordered Slip-On Flanges for a high-pressure fuel line to save 15% on costs.

The Problem:

The project specifications required 100% Radiography (RT) Testing on all joints.

- Fact: You cannot effectively X-Ray a Slip-On fillet weld. You can only X-Ray a Butt Weld.

Our Intervention:

The Dhanvika technical team flagged this mismatch immediately. We advised the client that if they used Slip-On flanges, they would fail the inspection phase. We helped them switch to Weld Neck Flanges (Class 600) immediately.

The Result:

The client avoided a massive penalty for non-compliance and passed all safety inspections on the first day.

Conclusion

- Buy Slip-On (SORF) if: You are running low-pressure water, air, or cooling lines and want to save on material costs.

- Buy Weld Neck (WNRF) if: You have high pressure, severe vibration, or need to X-Ray the joints for safety compliance.

Not sure which Class (150# vs 300#) you need? Send us your drawing and we will specify the correct flange for you.