Introduction

In the steel industry, a physical product is worthless without its paperwork.

When you buy Stainless Steel pipes, plates, or flanges, you aren’t just paying for the metal; you are paying for the assurance that it meets the chemical and mechanical standards you ordered.

This assurance comes in the form of a Mill Test Certificate (MTC).

At Dhanvika Global, we provide MTCs with every single shipment. But often, clients ask us: “What is the difference between a 3.1 and a 3.2 certificate?”

Here is the simple explanation of why this document matters for your project.

What is an MTC?

A Mill Test Certificate (MTC) is a quality assurance document generated by the manufacturer (the Mill). It proves that the material has been tested and meets the specific standards (like ASTM A312 or ASME B16.5).

It typically includes:

- Chemical Composition: (Does it have enough Chromium/Nickel?)

- Mechanical Properties: (Tensile strength, Yield strength)

- Heat Number: (The unique ID linking the pipe to the original molten batch)

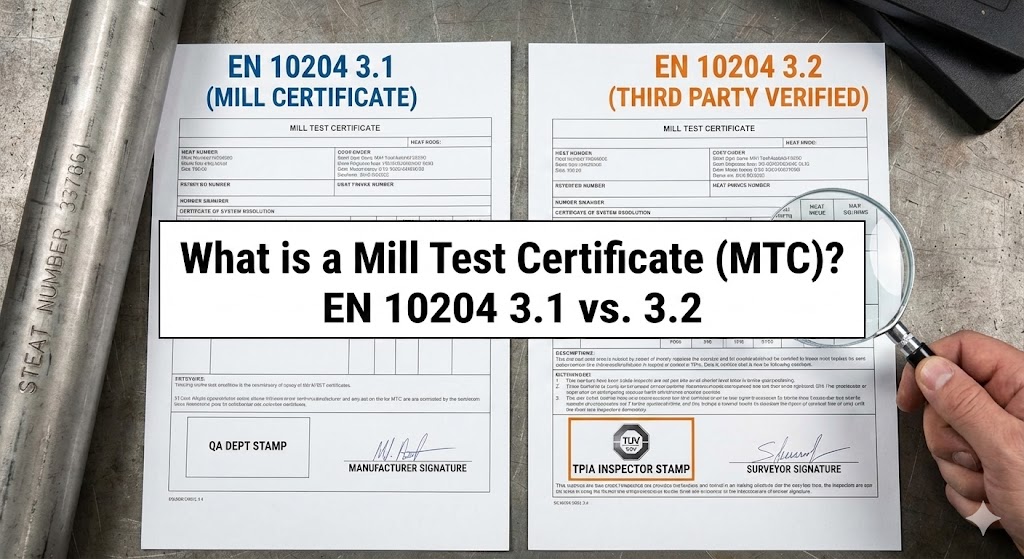

Type 3.1 Certificate (The “Standard”)

EN 10204 3.1 is the industry standard for 95% of projects.

- Who issues it? The Manufacturer (The Mill).

- Who validates it? The Mill’s own quality department, which must be independent of the manufacturing department.

- What it means: “We (the factory) certify that these pipes comply with the order, and here are our test results.”

- Cost: usually included in the product price.

Type 3.2 Certificate (The “Third Party” Verified)

EN 10204 3.2 is a much stricter standard, used for critical applications like high-pressure gas lines or offshore platforms.

- Who issues it? The Manufacturer AND an independent Third-Party Inspection Agency (TPIA) like Lloyds, TUV, DNV, or SGS.

- Who validates it? An external inspector visits the factory, witnesses the testing personally, and stamps the certificate.

- What it means: “We (The Third Party) watched them test it, and we certify it is true.”

- Cost: Expensive. You must pay for the surveyor’s daily fees.

⚔️ Comparison Table

| Feature | EN 10204 3.1 | EN 10204 3.2 |

| Trust Level | High (Standard) | Maximum (Verified) |

| Issued By | The Manufacturer | Manufacturer + Third Party (TPIA) |

| Witnessed By | Factory QA Dept | External Inspector (TUV/DNV) |

| Cost | Free / Included | High (Extra Charges Apply) |

| Lead Time | Instant | Delays (Waiting for inspector) |

🚩 Red Flag: How to Spot a Fake MTC

Unfortunately, fake certificates exist in the market. Here is how we verify MTCs at Dhanvika Global before we ship to you:

- Check the Heat Number: The number on the paper MUST match the number stenciled on the pipe. If they don’t match, the certificate is useless.

- Verify the QR Code: Modern certificates often have a QR code you can scan to verify authenticity.

- Material Specs: If an SS 304 MTC shows Nickel content below 8.0%, it is not SS 304. It is scrap.

Conclusion

- Ask for 3.1 for almost all standard industrial projects. It is sufficient proof of quality.

- Ask for 3.2 only if your end-client (like Aramco or Shell) explicitly demands it, as it will increase your cost and delivery time.

At Dhanvika Global, we believe in 100% transparency. You receive the MTC before the material is dispatched so you can verify it yourself.

Need Third-Party Inspection?

We regularly work with TUV, DNV, and SGS for export orders. Contact us to discuss your inspection requirements.